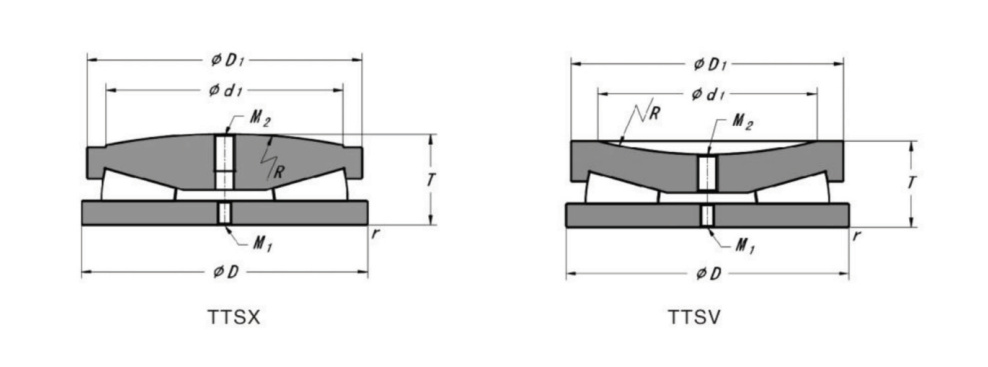

Outer dimension (mm) | Rated Load (KN) | Bearing Model | Weight (kg) | |||||||

D | D1 | d1 | T | R | M2 | M1 | rmin | Coa |

|

|

150 | 148 | 127 | 48 | 228.6 | M12 |

| 1.5 | 1630 | TTSV150 | 5 |

320 | 318 | 280 | 95 | 380 | M24 |

| 1.5 | 7370 | TTSV320 | 42 |

380 | 378 | 330 | 129 | 914.4 | M24 | M30 | 1.5 | 8550 | TTSX380 | 101 |

410 | 408 | 355 | 142 | 1016 | M24 | M30 | 3 | 11300 | TTSX410 | 130 |

440 | 438 | 380 | 130 | 508 | M24 | M36 | 3 | 18500 | TTSV440 | 140 |

495 | 492 | 432 | 146 | 558.8 | M24 | M36 | 3 | 19100 | TTSV495 | 198 |

525 | 522 | 460 | 180 | 1270 | M24 | M36 | 3 | 20380 | TTSX525 | 250 |

555 | 552 | 482 | 165 | 635 | M24 | M36 | 3 | 21380 | TTSV555 | 275 |

580 | 577 | 510 | 195 | 1422.4 | M24 | M36 | 3 | 21540 | TTSX580 | 310 |

610 | 607 | 533 | 178 | 762 | M30 | M42 | 3 | 24170 | TTSV610 | 350 |

640 | 637 | 550 | 185 | 762 | M30 | M42 | 3 | 28670 | TTSV640 | 410 |

710 | 637 | 550 | 214.8 | 1740 | M30 | M42 | 3 | 28670 | TTSX640 | 450 |

750 | 705 | 610 | 250 | 1600 | M30 | M42 | 4 | 31540 | TTSX710 | 850 |

800 | 745 | 650 | 260 | 1600 | M30 | M48 | 4 | 38430 | TTSX750 | 750 |

METALLURGY AND CONSTRUCTION