BEARING ACCURACY INSPECTION

ZYS can:

1. Do bearing inspection for dimension accuracy, rotation accuracy, clearance, vibration, residual magnetic field, contact angle, friction moment, appearance quality and parts inspection.

2. Offer the original test record.

3. Make calibration of radial clearance, vibration calibrator and calibration of piezoelectric ac-celerometer, working vibrator , and offer calibration certificate.

bearing accuracy inspection

bearing accuracy inspection

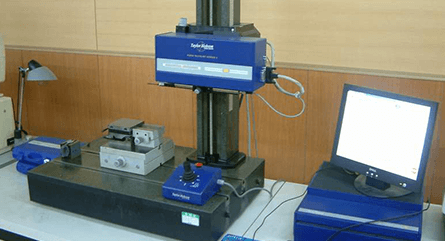

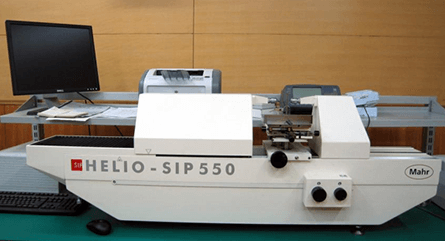

PRECISION METERING TEST

ZYS can:

1. Do transfer and calibration of the length, roundness and roughness

2. Do calibration of various indicator meters, torsion spring comparator, universal caliper, micrometer, lever micrometer

3. Do precision measurement of bearing parts

4. Do inspection of surface roughness, roundness, surface convexity, geometric tolerance for bearing parts and inspection of steel ball products with accuracy above G16.

Precision metering test

Precision metering test

BEARING PHYSICAL PROPERTIES INSPECTION

ZYS can do inspection of metallography, hardness, burn, ball crushing load, needle bending strength, crack, and offer original inspection records and original reports.

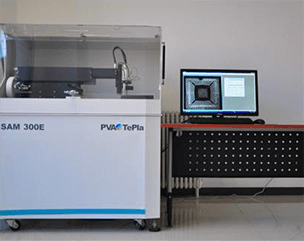

PRECISION INSPECTION OF SPECIAL MATERIALS

ZYS can make inspection of 3D morphology and internal defects of precision ceramic balls, high precision cemented carbide balls and hydrodynamic bearings.

INSPECTION OF CHEMICAL MATERIALS

ZYS can inspect:

1. Particle size and its distribution

2. Polymer molecular size and its distribution

ULTRASONIC OIL FILM INSPECTION

Detection range:

1. Thickness of lubricating oil film (0.1um-10mm)

2. Contact pressure (kPa to GPa)

3. Wear (<1um resolution)

4. Contact area

5. Fluid properties (aeration, degradation, viscosity, density)

6. Stress (bolt tension, structural load, subsurface Hertz, bulk material)

7. Corrosion

8. Crack growth

9. Microstructure of materials

Do you have the bearing question or problem? Please contact us. We will offer solutions for you.