Ball Bearing

-

Angular contact ball bearing

The inner and outer ring raceways of angular contact ball bearings have relative displacement in the direction of bearing axis. Therefore, angular contact ball bearings can carry combined loads, namely radial loads and axial loads. The axial load carrying capacity of angular contact ball bearings increases as the contact angle increases. Angular contact ball bearing is one kind of precision bearing which performs well in high-speed and high-precision applications.

Advantages of ZYS Angular Contact Bearings:

1. The outstanding speed performance.

2. Product size specifications increase.

3. Advanced heat treatment processes maximize the dimensional stability and hardness of bearing part and then reduce wear.

4. Designed with multiple preload levels to meet speed and rigidity requirements for a variety of applications.

5. Able to develop new products for special application conditions according to customers' needs.

The most common designs of ZYS Angular Contact Ball Bearings are:

1. Single row angular contact ball bearing

2. Double row angular contact ball bearing

3. Four point contact ball bearing

-

Ball screw bearing

Ball screw bearings can withstand large axial loads in a single direction, and can also withstand a certain radial load at the same time. Ball screw support bearings usually need to be used in double or multiple combinations, and the matching method is the same as angular contact ball bearings. ZYS can offer ISO metric ball screw bearings and non-ISO metric ball screw bearings, which are widely used for precision instruments and ball bearing lead screws.

-

Thrust angular contact ball bearing

ZYSN and ZYSF series thrust angular contact ball bearings are precision bearings, mainly used for screw drive. Aangular contact thrust ball bearing is a complete bearing unit consisting of a whole outer ring, two inner rings, steel balls, cages and sealing rings.

After assembly, the bearing is O - shaped (DB) with a contact Angle of 60. It can withstand both axial and radial loads by applying a preload through a precision lock nut.

Angular contact ball thrust bearings are sealed on both sides, grease lubricated and designed with relubrication structure. The cage is made of polyamide PA66-GF25 material and can work continuously for a long time under the working temperature below 120C.

-

Deep groove ball bearing

Deep groove ball bearings are the most common type and used in a wide range of applications, such as gearbox, instrument, motor, household appliances, internal combustion engine, traffic vehicles, agricultural machinery, construction machinery, roller skates and so on. Top three sales in ZYS is motorcycle bearing, motor bearing, agriculture bearing. Deep groove ball bearings are simple in design, non-separable, and requires simple maintenance.

Deep groove ball structure is also divided into seal and open structure. It has higher working speed, and can achieve a lower noise level. It mainly bears radial load, and also can bear axial load and radial load at the same time.

ZYS can produce a full range of deep groove bearings with different designs, variations and sizes.

(1) single row deep groove ball bearings

The most widely used type.

(2) stainless steel deep groove ball bearing

Resistant to corrosion caused by moisture and other media

(3) single row deep groove ball bearings with filled groove

Higher radial load carrying capacity.

(4)Double-row deep groove ball bearings

The bearing capacity has been significantly improved.

Roller Bearing

-

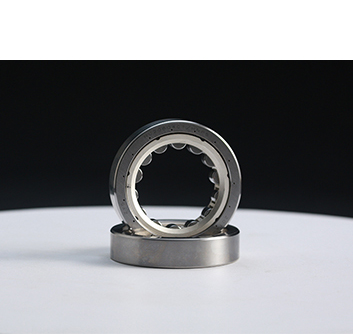

cylindrical roller bearing

The contact type of the cylindrical roller bearing roller and the raceway is line contact. The bearing capacity and rigidity of cylindrical roller thrust bearing are higher than that of the angular contact ball bearing (including the multi-coupling bearings), which belongs to the point contact, but the allowable rotation speed of the cylindrical roller bearing is lower. Most designs are separable and can be easily assembled and disassembled. Therefore, cylindrical roller bearings are often used in medium and large machine tools and machining centers where the load is large and the rigidity is high, while the rotational speed is relatively low.

ZYS can design and offer full range of single row cylindrical roller bearings and double row cylindrical roller bearings. In order to meet the requirements of high speed, high rigidity and long life, ZYS has developed high-speed hybrid ceramic cylindrical roller bearing, that is, the inner and outer ring of the bearing is made of high-quality bearing steel material, and the cylindrical roller is made of silicon nitride ceramic. Compared with standard steel cylindrical roller bearings of the same structure and size, it has the advantages of high speed performance, high rigidity, low friction, long life and high reliability, which can significantly improve the production efficiency and extend the life of machine.

-

Cross cylindrical roller bearing

ZYS precision cross cylindrical roller bearings can simultaneously bear radial load, bidirectional thrust load and overturning moment, and have high rigidity.

This type of bearing is suitable for rotating tables in machining centers, joint parts or rotating parts of industrial robots, rotating parts of manipulators, medical equipment, precision rotating tables, IC manufacturing devices, measuring instruments, etc.

Inside the cross cylindrical roller bearing, the rollers are arranged at 90°to cross each other vertically, and the structure is compact. ZYS precision cross cylindrical roller bearings have three structural forms: with full complement rollers, with cages, and with interval retainers. Among them, bearings with full complement rollers are suitable for low speed and heavy load conditions; while bearings with cage and with interval retainer is suitable for the working condition of small friction torque and high speed.

ZYS precision cross cylindrical roller bearings are divided into seven structural series: RB series, RE series, RU series, RA series, RA-C series, CRB series and CRBH-A series.

Characteristics of cross cylindrical roller bearings

High precision: The inner or outer ring of the cross cylindrical roller bearing can be separated, and the bearing gap can be adjusted, so that it can still obtain higher rotation accuracy under load.

High load carrying capacity: Compared with the traditional cage, the spacer retainer of the cross cylindrical roller bearing can increase the effective contact length of the roller, thereby greatly improving the load carrying capacity; at the same time, the spacer retainer guides the full length of each roller, which effectively prevents the roller from tilting. In addition, the spacer retainer keeps the load area symmetrically distributed, preventing end-face contact caused by the asymmetry of the load area, reducing friction and wear, and improving bearing life.

High stiffness: Compared with double row angular contact ball bearings, cross cylindrical roller bearings can bear the load in all directions with only one row of crossed cylindrical rollers, greatly reducing the width of the bearing, and meeting the requirements of compact structure. Because the roller is loaded, the stiffness of the cross cylindrical roller bearings can also be increased by 3-4 times when the rigidity of the installed components remains unchanged.

Simple operation: cross cylindrical roller bearing has the separated inner ring or outer ring. After the roller and the spacer cage are installed in bearing, the inner/ outer ring is fixed with another part that can not be separated to prevent separation from each other, so the installation operation is very simple.

Bearing Parts and superhard material products

-

Bearing ball

Bearing ball acts as a rolling element in the ball bearing to carry and transfer load, and its quality directly affects the dynamic performance and service life of the bearing. ZYS can offer several kinds of ball bearing balls, including ceramic ball, steel ball, carbide ball.

In order to ensure the quality of bearing balls, the following aspects should be paid attention to:

1) Strict selection of high quality materials

2) Optimization of processing technology to improve bearing ball accuracy

3) Strict quality inspection and process control

-

Bearing cage

Bearing cage, also called bearing retainer, refers to the bearing part that fully or partially encloses the rolling elements and moves with them to isolate the rolling elements and usually guide the rolling body and keep it in the bearing. Bearing cages are divided into metal cages and non-metallic cages (Nylon, PTFE, plastic cage) by material type. There are also composite material cages.

-

Resin bond superhard material products

Product features of Resin bond superhard material products:

Good self-sharpening,sharp grinding,high efficiency,good surface quality, short production cycle, and cost-effective.

Product classification of Resin bond superhard material products:

CBN abrasive tools, diamond abrasive tools.

Processing range of Resin bond superhard material products:

Cemented carbide, ceramics, magnetic materials, semiconductor materials, composite superhard materials, high-speed steel, bearing steel, abrasive steel, stainless steel, cast iron and other materials.

-

Metal bond superhard material products

Product features of Metal bond superhard material products:

It has good rigidity, high strength, good wear resistance, long service life, good shape retention, and it can withstand larger loads.

Product classification of Metal bond superhard material products:

CBN abrasive tools, diamond abrasive tools.

Processing range of Metal bond superhard material products:

Non-metallic materials such as glass, ceramics, stone, concrete, and magnetic materials.

Special Bearing

-

Precision Robot Bearings

ZYS precision robot bearings are mainly used in industrial robot RV reducers, harmonic reducers and robot joints. Industrial robotic bearings are developed for working conditions in which the robot bearings are small in size, light in weight and high in speed. ZYS mainly provides thin-wall bearings for RV reducers, flexible bearings for harmonic reducers, thin-wall bearings with equal sections, and crossed cylindrical roller bearings.

-

hydrodynamic bearing

Basic forms and recommened applications of fluid dynamic bearings:

According to different loads, a hydrodynamic bearing may be hydrodynamic journal bearing or hydrodynamic thrust bearing.

A hydrodynamic journal bearing may be designed with various structures, including three-oil wedge bearing, step-face bearing, tilting-pad bearing, etc.

Three-oil wedge bearings and step-face bearings are fixed-pad mult-wedge bearing. During operation, many hydrodynamic oil films are formed, with good rotary accuracy, self-alignment, high rigidity and damping, better high speed stability.They are commonly used for high-speed light-load bearing.

Tilting-pad bearings are tilting multi-oil wedge bearings, of which pads may be automatically adjusted for inclination with varied load and speed. They are one of bearings with the best stability and mainly used for high-speed and light-load bearing.

A hydrodynamic thrust bearing may be designed with various structures, including fixed-pad inclined thrust bearing, fixed-pad inclined-planar thrust bearing, fixed-pad step-face thrust bearing, tilting-pad thrust bearing, etc. Fixed-pad inclined thrust bearings, fixed-pad inclined-planar thrust bearings, fixed pad step-face thrust bearings are fixed-pad thrust bearing and the main form of thrust plain bearings. They apply to medium and small-scale light-load thrust plain bearings.

Tilting-pad thrust bearings apply to important large and medium scale thrust plain bearings.

-

Rolling mill bearing

ZYS can offer wide range of bearing products and bearing solutions for steel industry.ZYS bearings for rolling mill mainly include four row cylindrical ro ller Bearings, rour row rapered roller bearings, double row tapered roller bearings and screw-down bearings.

-

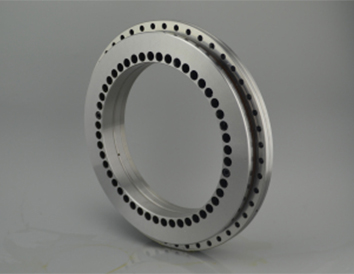

Slewing bearing

ZYS can offer five types of slewing ring bearings, including single row four point contact ball slewing bearing, double row different ball diameter slewing bearing, single row cross roller slewing bearing,roller&ball combination slewing bearing and three-row cylindrical roller slewing bearing.

-

Precision rotary table bearing

ZYS can offer YRT series, YRTS series, ZKLDF series, YRTM series, YRTSM series rotary table bearings. About the performance comparison of YRT, YRTS and ZKLDF series bearings with the same size, the limit speed of ZKLDF, YRTS, YRT series bearings decrease in turn while the overturning rigidity of YRTS, YRT and ZKLDF series bearings decrease sequentially. YRTM or YRTSM rotary table bearings add a set of angular displacement monitoring system on the basis of YRT or YRTS series bearings, to overcome the defect of open-loop control of diagonal displacement control, and realize closed-loop control of rotary table or indexing plate, greatly improving the positioning accuracy of angular displacement.

Product structure Thrust / radial cylindrical roller bearings YRT and YRTS series are composed of two thrust roller bearings and one radial cylindrical roller bearing. Due to the special design of the internal structure of YRTS series bearing, higher limit speed can be achieved. Thrust angular contact ball bearings ZKLDF series consist of an integral outer ring, two inner rings and two sets of steel balls and cage assemblies. Its contact angle is 60, and it is especially for the conditions with high requirements on high speed, high axial and radial loads and overturning moment. Product Features ZYS turntable bearings are ready-to-install high-precision turntable bearings, suitable for occasions with high precision requirements and combined load. They can withstand radial loads, bidirectional axial loads and overturning moments with negative clearance. ZYS turntable bearings have the characteristics of high precision, high rigidity and high load capacity. In order to facilitate transportation and installation, screw holes are opened on the inner ring and the outer ring, and the entire set of bearings is fastened with positioning screws. The bearings are preloaded at the factory, and there is no need to adjust the clearance for installation. -

Wind turbine bearings

Wind turbines are generally divided into doubly-fed, direct-drive and semi-direct-drive types. Various bearings are widely used in wind turbines. The largest number of bearings and the most complete types are traditional double-fed fans. Up to 32 sets of bearings can be used for wind turbines. Therefore, the selection of bearings is very important to ensure the safe and stable operation of wind turbines.

The wind turbines are installed in the field with windy sand or relatively high humidity. The working conditions of wind turbine bearings are very harsh, and the range of temperature, humidity and load toleration varies greatly. In particular, yaw bearings and pitch bearings need to withstand large axial forces and overturning moments; while gearbox bearings need to withstand huge shock loads during starting and braking and have low friction torque and high running flexibility when starting at low speed.

Wind turbine bearings are generally divided into the following types: yaw bearings, pitch bearings, main shaft bearings, gearbox bearings and generator bearings. The technical requirements are different depending on the bearing type. In 2001, ZYS became the first company that undertook the project of National Ministry of Science and Technology - Development of key bearings for large and medium wind turbine generator" . ZYS has acquired the core designing, manufacturing and testing technology in yaw bearing, pitch bearing, main bearing, gearbox, and generating motor bearing in wind turbine system. We have also cultivated a number of professional staff in wind bearing design, property analyses, manufacturing and testing. We cultivated the first post doctor in the field of wind power generator in China and developed specialized integrated design and analysis software that can conduct load spectrum analysis of wind turbine generator bearing, stress analysis, design and verification of key structural parameters, calculation of effective hardened layer depth and gear and bolt strength check etc. Properties of our wind turbine generator bearings have reached international advanced level. Up to now, we have applied many national patents in wind turbine generator bearing, such as Slewing bearing for 1.0MW wind turbine generator, slewing bearing for 15MW wind turbine generator , self-lubricating cage for slewing bearing , long life& high load three row roller combination slewing bearing , and Intelligent wind turbine generator bearing based on Internet of things, etc. In particular, the exclusive patent of “Intelligent wind turbine generator bearing based on internet of things” can realize remote monitoring, fault warning and diagnosis.