The Milestone of ZYS spindle products:

- 1958 China's first electric spindle

- 1980 China's first pneumatic static spindle

- 1995 China's first machining center spindle

- 1999 China's first engraving and milling spindle

- 2006 China's first precision turning spindle

- 2016 China's first permanent magnet workpiece spindle

- 2017 Research and development of high-end machining center electric spindle

- 2018 Research and development of intelligent spindle

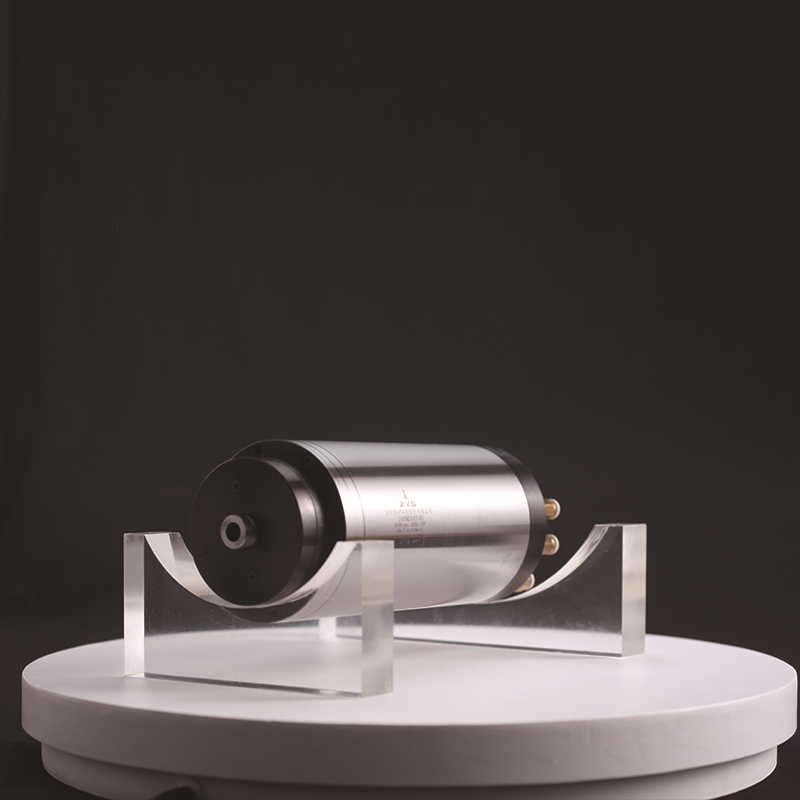

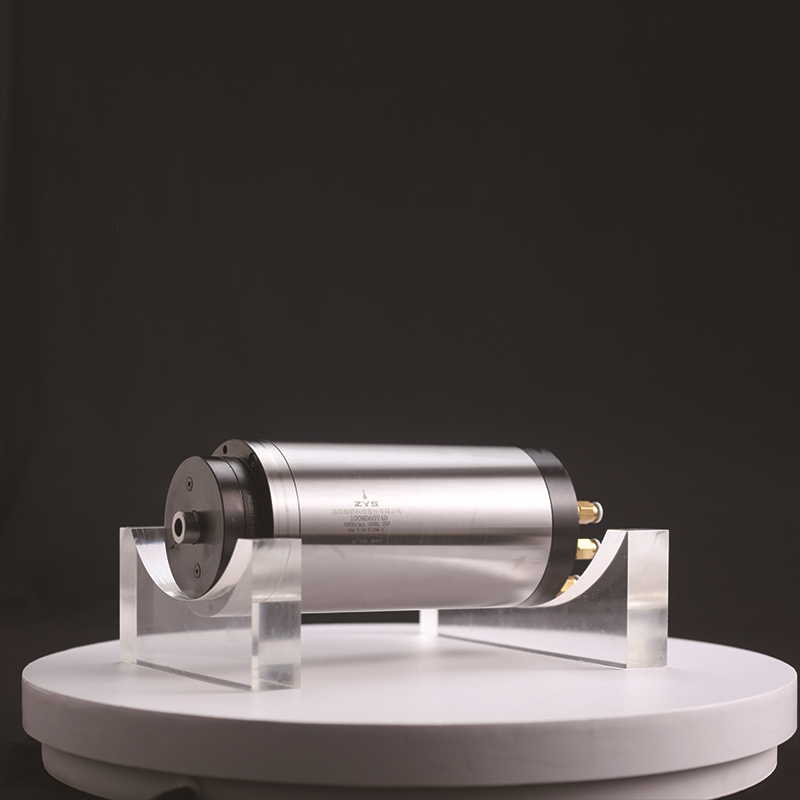

Product features of ZYS motorized spindles:

1. Alternative import

All key components of the product are independently researched and developed, and the performance has reached the same level of foreign products, and the quality is reliable.

2. Professional customization

According to the actual work situation of the customer, the optimal design obtained from various factors can be integrated to meet the individual needs.

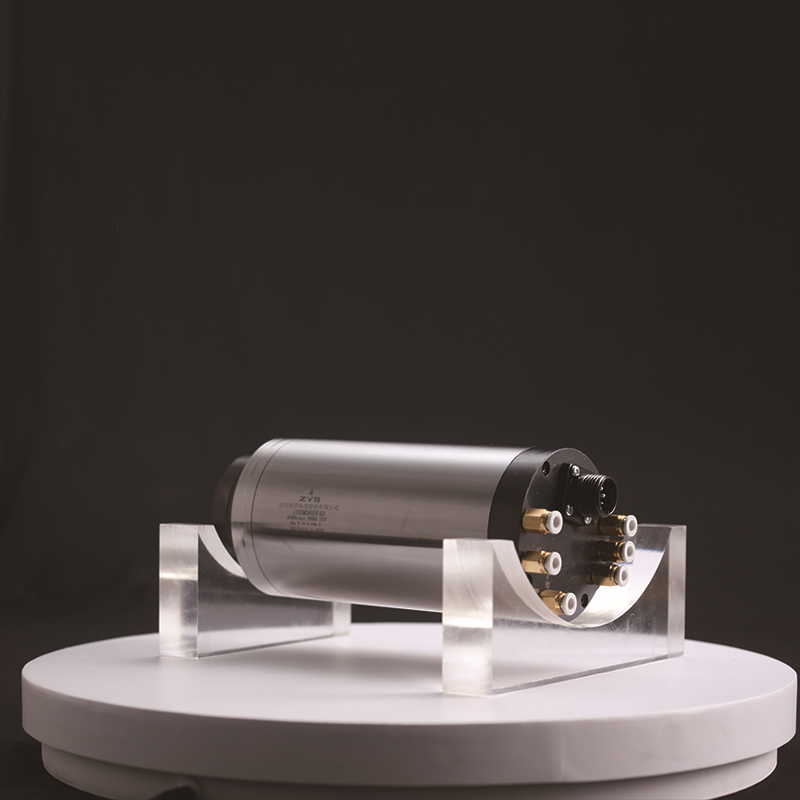

3. Flexible configuration

The spindle can be equipped with temperature sensor (temperature measurement and temperature switch), vibration sensor, proximity switch, encoder, rotary joint, etc. according to customer's requirements. At the same time, the spindle electrical components adopt well-known brands and have good compatibility.

4. Quality service

Pre-sales technical exchange is sufficient, after-sales service response is fast, product maintenance cycle is short.

The brief introduction of ZYS spindle workshop:

In 1958, Luoyang Bearing Research Institute set the 308 Research Group to develop the spindles. After more than 60 years of development, it has gradually developed from the original scientific research institution into the company which collects the spindle research, development and production as a whole. The production area of spindle workshop reached 32,800 square meters. Luoyang Bearing Research Institute Co., Ltd. is the main drafting unit of spindle national standard, the chairman unit of the spindle branch of China Machine Tool Industry Association, the leader of the 863 spindle project, the responsible unit of the “Eighth Five-Year Plan”, “Ninth Five-Year Plan”, “Tenth Five-Year Plan” and major national science and technology projects for CNC machine tool spindle. It is also the location of Henan Machine Tool Spindle Engineering Technology Research Center.

Luoyang Bearing Research Institute Co., Ltd. has an annual production capacity of 6000 sets of spindles.

ZYS full support on motorized spindles:

Luoyang Bearing Research Institute Co., Ltd. has excellent technical support, production support, quality system support and test equipment support for motorized spindle.

Technical support:

I. Shaft analysis and optimization

In cooperation with Tsinghua University (a well-known university in China), we integrated ZYS expert experience accumulated in the high-speed shafting dynamic analysis and developed the analysis software for spindle shafting dynamic.

We achieve the accurate calculation and analysis of the spindle rotor system under different stress conditions, different bearing assembly forms and different bearing spans. Through parameter adjustment and optimization of the shafting mechanism, the quantitative value of key indicators can be obtained during the design initial stage, such as spindle mode, bearing service life and critical speed.

II. Motor design and optimization

In cooperation with Hefei University of Technology, we integrated our expert experience and database accumulated in the design and analysis of high-speed motors, and developed the design and analysis software for spindle motors.

After the electromagnetic design of the spindle high-speed motor, we can analyze the spindle torque, output current and overload capacity at rated operating point through computer simulation, and calculate the motor heating condition under the simulated working condition to ensure that the spindle design can meet the requirements under actual situation.

III. Intelligent technology of machine tool spindle

ZYS spindle is equipped with various sensors such as temperature, vibration, displacement and distance. Sensor signals are continuously monitored by an intelligent system. It can prevent and protect the spindle when the temperature rises, the vibration intensifies, or the life of fixture is about to expire.

IV. Independent and complete design system

ZYS has professional technical team and we have our independent and complete design system on the thermal analysis, drive system matching, cooling system design, lubrication system design, main bearing design, motor design, shaft design for the spindle research and development.

V. Multi-field coupling simulation

The finite element simulation software is used to analyze the temperature field distribution, bearing stress variation and spindle thermal deformation law of the current spindle.

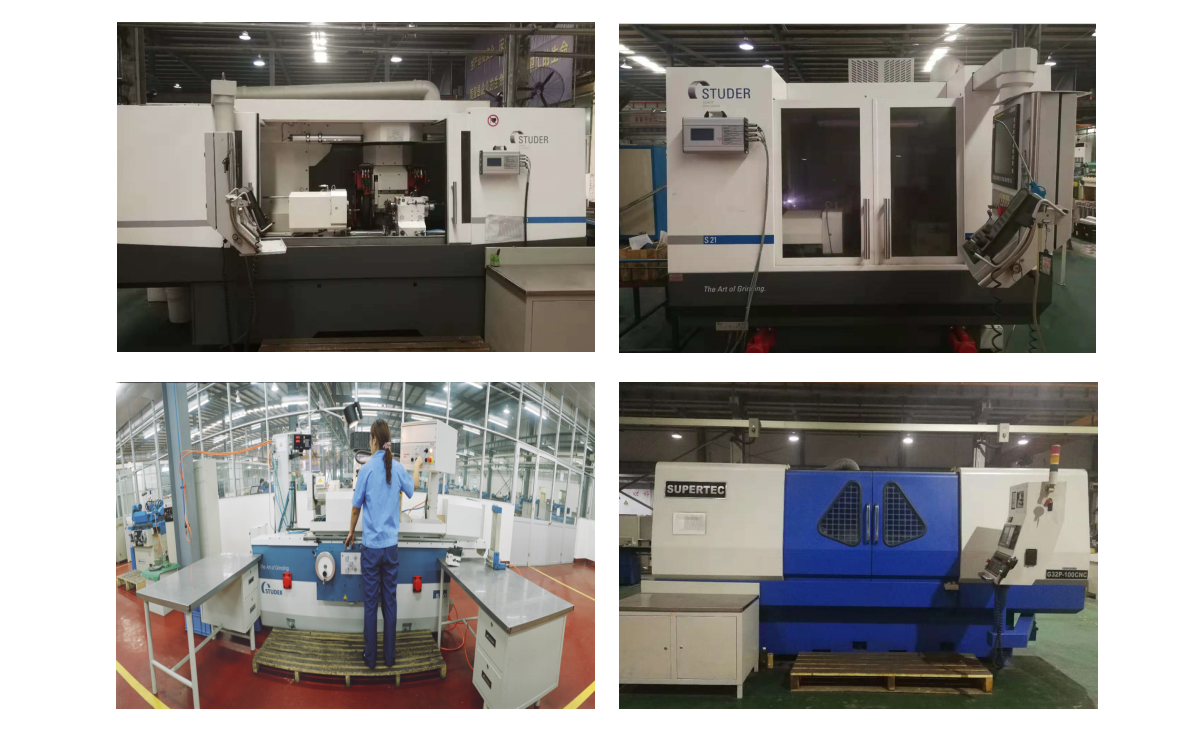

Production support:

I. Excellent production guarantee ability

II. High-power motors, precision bearings and parts

High-precision spindle parts are produced by optimal control from materials, heat treatment, stability treatment and precision machining.

The motor is completely developed independently. Motor has asynchronous aluminum rotor, asynchronous copper rotor, and permanent magnet synchronous motor.

Quality support:

I. Comprehensive inspection and control

II. Perfect quality system

ZYS has a sound quality system and has passed ISO and CE certification, which provides a strong guarantee for the quality and stability of electrical spindle products.

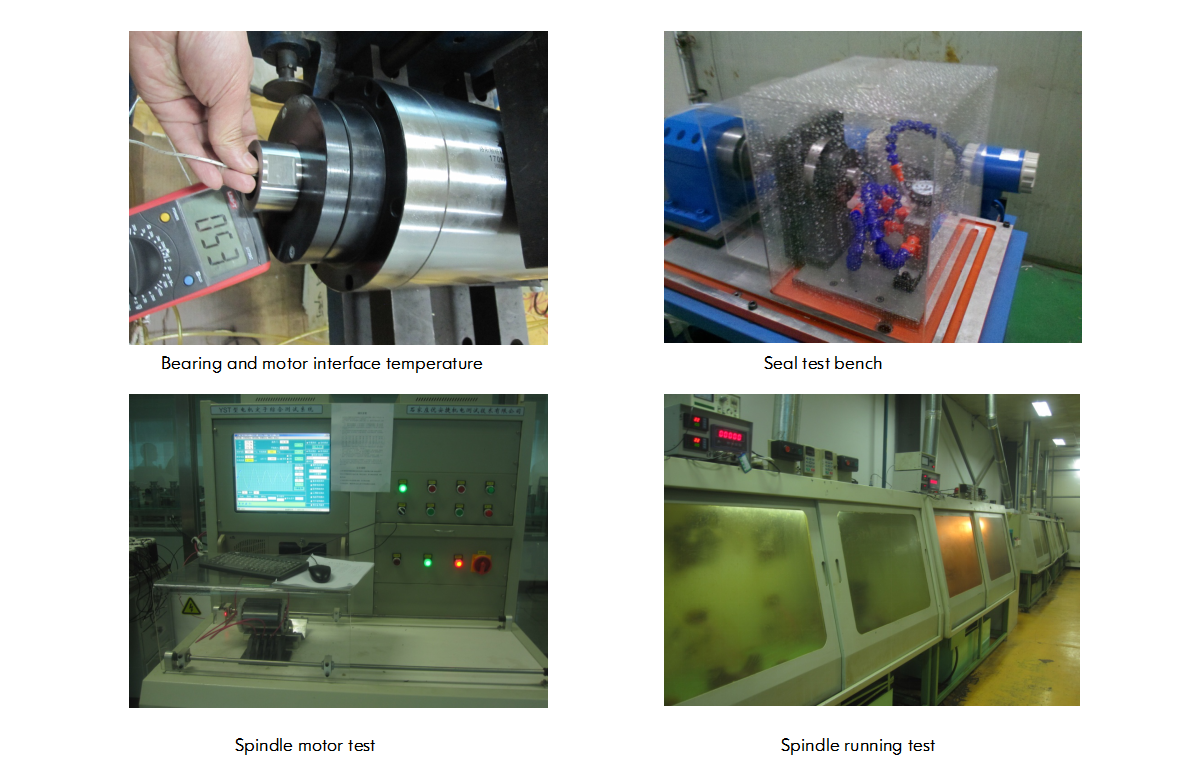

Test support:

I. Rigid test test bench

ZYS rigid test bench has the advantages of high measurement accuracy, low repeatability error, and automatic stepless acceleration. It can verify the rigidity of the spindle and provide data support for the shaft system design. It can ensure the consistency of the rigidity of the finished spindle.

II. Motor torque test

ZYS motor torque test can test the torque, heat generation, efficiency, overload capability and power factor of the electric spindle. ZYS motor torque test also can realize the torque-speed characteristic curve mapping.

III. Comprehensive performance testing

Spindle accuracy control | Spindle dynamic test control before delivery |

1.Unique identification number of important part | 1. Real-time monitoring of the spindle in no-load test |

2. File important processing dimension record as quality documents for technical analysis

| 2. Improve the inspection standard: the spindle vibration value is increased from less than 1.5mm/s to less than 1mm/s at the maximum speed, and the highest standard is less than 0.6mm/s. |

3. Increase the part accuracy and shape accuracy by 30% by improving equipment processing accuracy and optimize machining process. | 3. The temperature rise of the spindle is controlled at an optimum state of 15 degrees at the maximum speed.

|

4. The accuracy of shaft end runout of the assembled product is less than 2um, and partly 1um. | 4. Spindle rigidity test |

ZYS 100% spindle products pass comprehensive performance test.

Product Case | 170MD09Z30 | ||

Application background | In order to improve the efficiency of grinding tools, one of our customers put forward high-power and high-stiffness requirements on the basis of 170MD09Z20. Our R&D department developed 170MD09Z30 based on market development and customer requirements. | ||

Main parameters of grinding spindle

| Rated speed: 9000r/min | Rated power: 30Kw (S6) | Accuracy: inner hole runout 0.002mm; end face runout 0.002mm. |

Indicator improvement | Compared with 170MD09Z20, the power is increased by 50%, and the stiffness is increased by 20%. | ||

Client feedback | The use performance is improved obviously, the processing quality is stable, and the service life is reliable. | ||

Product Case | Comprehensive solution for segmental grinding machine |

Application background | In the process of machining tools in a southern enterprise, the segmental grinding machine has the problem of low grinding efficiency, and the customer hopes to increase the processing cycle by about 5S. After receiving the customer's entrustment, ZYS investigated the processing conditions in detail, and combined the characteristics of the processing tools to propose a comprehensive solution of workpiece axis + rough grinding spindle + fine grinding spindle. |

Main parameters of segmental grinding machine | Workpiece grinding method: center-moving grinding with rough and fine grinding. Diameter range of grinding workpiece: 0.05-20.0mm. Automatic feeding and receiving by manipulator. |

ZYS spindle solution | Workpiece motorized spindle: 120MD03Z1.8-HM Rough grinding spindle: 170MD09Z12HM Fine grinding spindle: 120MD12Z3.4HM |

Type | Motor parameter | Dimension |

|

| |||||||||||||

| Power (KW) S6/ S1 | Voltage (V) | Current (A) S6/ S1 | Speed (r/min) | Frequency (Hz) | D | L | D1 | L1 | D2 | L2 | d1 | L1 | M | L2 | Bearing P4 | Remark |

80MD150Y0.8 | 0.8/0.5 | 360 | 3/1.43 | 150000 | 2500 | 80 | 110 | 8 | 12 | - | - | 3.175 | 14 | - | - | 1-VEB08/NS 1-VEB08/NS |

|

80MD120Y0.9 | 0.9/0.55 | 220 | 4.6/2.8 | 120000 | 2000 | 80 | 150 | 48 | 8 | 10 | 5 | 5 | 9 | M5 | 8 | 1-VEB10/1-VEB10 | 2GDZ120 |

80MD90Y2.5 | 2.5/1.5 | 220 | 10.8/6.5 | 90000 | 1500 | 80 | 170 | 58 | 22 | 11 | 10 | 6 | 11 | M6 | 11 | 2-B7001/1-B7001 | GDZ90 |

100MD90Y3 | -/3 | 350 | -/8 | 90000 | 1500 | 100 | 165 | 80 | 24 | 16 | 8 | 9 | 16 | M8X2 | 21 | 2-7003CE/2-7002CE |

|

120MD75Y3.5 | 3.5/2.1 | 350 | 9/5.4 | 75000 | 1250 | 120 | 190 | 12 | 24 | 16 | 9 | 9 | 17 | M9*1.25 | 14 | 2-B7003/2-B7001 | 2GDZ75 |

80MD60Y1.5 | 1.5/0.9 | 153 | 9/5.4 | 60000 | 1000 | 80 | 160 | 55 | 24 | 14 | 9 | 8 | 16 | M8 | 14 | 2-B7002/1-B7002 | DZ60B |

100MD60Y4 | 4/2.5 | 350 | 10/6.3 | 60000 | 1000 | 100 | 185 | 66 | 24 | 16 | 8 | 8 | 13 | M8*1 | 15 | 2-B7003/2-B7003 | GDZ60B |

120MD60Y6 | 6/3.6 | 350 | 16/10 | 60000 | 1000 | 120 | 220 | 70 | 11 | 18 | 11 | 10 | 19 | M10*1.5 | 19 | 2-B7004/2-B7003 | 2GDZ60 |

120MD60Y7 | -/7 | 380 | -/15 | 60000 | 1000 | 120 | 222 | 90 | 28 | 23 | 10 | 14 | 22 | M14*1.5 | 20 | 2-H71905HQ1/2-H71904HQ1 |

|

120MD51Y8 | 8/4.8 | 350 | 20/12 | 51000 | 850 | 120 | 250 | 70 | 12 | 23 | 13 | 14 | 23 | M14*1.5 | 19 | 2-B7005/2-B7004 | 2GDZ51 |

120MD48Y5.8 | 5.8/3.5 | 350 | 15/9 | 48000 | 800 | 120 | 230 | 80 | 23 | 23 | 14 | 14 | 24 | M14*1.5 | 19 | 2-B7005/2-B7004 | GDZ48 |

120MD42Y9 | 9/5.5 | 350 | 20/12 | 42000 | 700 | 120 | 230 | 90 | 27 | 23 | 12 | 14 | 24 | M14*1.5 | 19 | 2-B7005/2-B7004 | GDZ42S |

120MD36Y8.5 | 8/5.5 | 350 | 18/11 | 36000 | 600 | 120 | 255 | 92 | 30 | 28 | 12 | 16 | 27 | M16*1.5 | 20 | 2-B7006/2-B7005 | GDZ36B |

120MD36Y8.5C | 8/5.5 | 350 | 18/11 | 36000 | 600 | 120 | 255 | 92 | 28 | 33 | 15 | 20 | 34 | M20*1.5 | 20 | 2-B7007/2-B7005 | GDZ36C |

150MD36Y11 | 11/7 | 350 | 30/15.6 | 36000 | 600 | 150 | 270 | 105 | 32 | 33 | 14 | 20 | 34 | M20*1.5 | 20 | 2-B7007/2-B7006 | 2GDZ36 |

150MD36Y11A | -/11 | 360 | /22 | 36000 | 1200 | 150 | 270 | 116 | 30 | 33 | 13 | 20 | 34 | M20*1.5 | 20 | 2-B7007/2-B7006 |

|

120MD30Y11 | 11/6.6 | 350 | 30/17.8 | 30000 | 1000 | 120 | 315 | 70 | 10 | 33 | 7 | 20 | 34 | M20*1.5 | 19 | 2-B7007/2-B7006 | 2GDZ30N |

120MD24Y12 | 12/7.2 | 350 | 30/18 | 24000 | 800 | 120 | 315 | 70 | 10 | 43 | 8 | 22 | 38 | M22*2 | 24 | 2-B7009/2-B7006 | 2GDZ24N |

150MD24Y12.5 | 12.5/7.5 | 350 | 26.7/16 | 24000 | 400 | 150 | 310 | 98 | 32 | 38 | 19 | 22 | 38 | M22*2 | 26 | 2-B7008/2-B7007 | GDZ24A |

150MD24Y16 | 16/10 | 350 | 38/23 | 24000 | 800 | 150 | 320 | 105 | 30 | 43 | 18 | 25 | 42 | M25*2 | 25 | 2-B7009/2-B7007 | 2GDZ24 |

150MD24Y16A | -/16 | 380 | -/30 | 24000 | 800 | 150 | 331 | 122 | 37 | 47 | 16 | 28 | 44 | M28*2 | 25 | 2-B7010/2-B7009 |

|

170MD24Y22 | 22/14 | 350 | -/30.2 | 24000 | 800 | 120 | 305 | 110 | 40 | 43 | 22 | 25 | 42 | M25*2 | 24 | 2-B7009/HQ12-B7008/HQ1 |

|

150MD18Y14.5 | 14.5/8.6 | 350 | 32/20 | 18000 | 300 | 150 | 327 | 110 | 38 | 43 | 22 | 25 | 40 | M25*2 | 30 | 2-B7009/2-B7008 | GDZ18A |

170MD18Y16 | 16/10 | 350 | 35/21.2 | 18000 | 600 | 170 | 305 | 110 | 40 | 43 | 22 | 25 | 42 | M25*2 | 24 | 2-B7009/2-B7008 | GDZ18R |

170MD15Y20 | 20/12 | 350 | 46.3/27.8 | 15000 | 500 | 170 | 320 | 116 | 38 | 53 | 17 | 32 | 50 | M30*2 | 25 | 2-B7011/2-B7009 | 2GDZ15 |

170MD15Y16 | 16/10 | 350 | 35/21.2 | 15000 | 500 | 170 | 325 | 116 | 38 | 48 | 24 | 28 | 47 | M28*2 | 25 | 2-B7010/2-B7009 | GDZ15R |

170MD15Y25A | -/25 | 380 | -/46 | 15000 | 500 | 170 | 414 | 140 | 38 | 53 | 18 | 32 | 49 | M32*2 | 23 | 2-B7012/2-B7010 |

|

200MDF15Y28 | 28/18 | 380/300 | 44/35 | 15000/8000 | 500/267 | 200 | 430 | 140 | 42 | 53 | 25 | 32 | 50 | M30*2 | 28 | 2-B7011/2-B7010 |

|

170MD12Y16 | 16/10 | 350 | 36/22 | 12000 | 400 | 170 | 330 | 124 | 40 | 53 | 22 | 36 | 40 | M33*2 | 30 | 2-B7011/2-B7009 | GDZ12R-10 |

170MD12Y20 | 20/12 | 350 | 41.5/25 | 12000 | 400 | 170 | 370 | 124 | 40 | 53 | 22 | 36 | 40 | M33*2 | 30 | 2-B7011/2-B7009 | GDZ12R-12 |

170MD12Y32 | 32/20 | 350 | 36/22 | 12000 | 400 | 170 | 370 | 124 | 40 | 53 | 22 | 36 | 40 | M33*2 | 30 | 2-B7011/2-B7009 |

|

250MD10Y17 | 17.6/11 | 350 | 38.5/24 | 10000 | 334 | 250 | 350 | 140 | 15 | 53 | 28 | 25 | 35 | M24*1.5 | 33 | 2-B7011/2-B7009 |

|

170MD09Y20 | 20/12.5 | 350 | 43/26.9 | 9000 | 300 | 170 | 383 | 124 | 40 | 53 | 22 | 36 | 40 | M33*2 | 30 | 2-B7011/2-B7009 | GDZ09 |

210MD09Y33 | 33/20.6 | 350 | 70/43.8 | 9000 | 300 | 210 | 403 | 140 | 44 | 55 | 54 | - | - | Cone 1:8 |

| 2-B7212/2-B7009 | 2GDZ09 |

210MD09Y33B | -/33 | 350 | 70 | 9000 | 300 | 210 | 522 | 165 | 70 | 68 | 53 | 45 | 55 | M42*2 | 40 | 3-7014/2-7211 |

|

210MD06Y20 | -/20 | 350 | 42.5 | 6000 | 200 | 210 | 491 | 140 | 44 | 55 | 54 | - | - | Cone 1:8 | 46 | 2-7212/2-B7009 |

|

200MD06Y20 | -/20 | 380 | - | 6000 | 200 | 200 | 557 | 165 | 20 | 77 | 123 | - | - | Cone 1:10 | 66 | 4-7016/2-7011 |

|

120MD75Z3.5 | 3.5/2.2 | 350 | -/9 | 75000 | 1250 | 120 | 190 | 65 | 24 | 16 | 9 | 9 | 17 | M9*1.25 | 14 | 2-H71903HQ1/2-H7001HQ1 |

|

100MD60Z4 | 4/2.5 | 350 | 10/6.3 | 60000 | 1000 | 100 | 185 | 76 | 26 | 16 | 8.5 | 8 | 14 | M8*1 | 15 | 2-H7003HQ1/2-H7003HQ1 |

|

120MD48Z7 | 7/4.5 | 350 | 15.6/9.8 | 48000 | 800 | 120 | 230 | 90 | 25.5 | 23 | 11.5 | 14 | 24 | M14*1.5 | 19 | 2-H7005HQ1/2-H7004HQ1 |

|

120MD36Z9.5A | 9.5/6 | 350 | -/12.6 | 36000 | 600 | 120 | 255 | 94 | 36 | 28 | 14 | 16 | 27 | M16*1.5 | 20 | 2-H7006HQ1/2-H7005HQ1 |

|

150MD36Z11A | -/11 | 360 | -/22 | 36000 | 1200 | 150 | 270 | 116 | 30 | 33 | 13 | 20 | 34 | M20*1.5 | 20 | 2-H7007HQ1/2-H7006HQ1 |

|

120MD24Z5.5 | 5.5/3.3 | 250 | 18/11 | 24000 | 400 | 120 | 255 | 92 | 30 | 28 | 12 | 16 | 27 | M16*1.5 | 20 | 2-B7006/2-B7005 | GDZ24K |

150MD24Z16 | 16/10 | 350 | 38/24 | 24000 | 800 | 150 | 327 | 121 | 30 | 43 | 19 | 25 | 42 | M25*2 | 25 | 2-B7009HQ1/2-H7007HQ1 |

|

150MD24Z16-YT | -/16 | 380 | -/30 | 24000 | 800 | 150 | 331 | 122 | 37 | 47 | 16 | 28 | 44 | M28*2 | 25 | 2-H7010HQ1/2-H7009HQ1 |

|

150MD18Z9 | 9/5.5 | 350 | 22.4/13.5 | 18000 | 300 | 150 | 290 | 95 | 40 | 38 | 18 | 22 | 36 | M22*2 | 28 | 2-B7008/2-B7007 | DZ18B |

170MD18Z16 | 16/10 | 350 | -/19.7 | 18000 | 300 | 170 | 340 | 120 | 46 | 43 | 20 | 25 | 42 | M25*2 | 26 | 2-B7009/2-B7007 | GDZ18G |

170MD15Z25 | -/25 | 380 | -/46 | 15000 | 500 | 170 | 414 | 140 | 38 | 53 | 18 | 32 | 49 | M32*2 | 23 | 2-H7012HQ1/2-H7010HQ1 |

|

170MD15Z16 | 16/10 | 350 | 35/21.2 | 15000 | 500 | 170 | 325 | 116 | 38 | 48 | 24 | 28 | 47 | M28*2 | 25 | 2-B7010/2-B7009 |

|

170MD15Z20 | 20/12 | 350 | 46.3/27.8 | 15000 | 500 | 170 | 320 | 116 | 38 | 53 | 17 | 32 | 50 | - | 25 | 2-B7011/2-B7009 |

|

170MD12Z20 | 20/12 | 350 | 41.5/25 | 12000 | 400 | 170 | 370 | 124 | 40 | 53 | 22 | 36 | 40 | M33*2 | 30 | 2-B7011/2-B7009 |

|

160MDF09Z9 | -/9 | 350 | 19 | 9000 | 300 | 160 | 280 | 120 | 42 | 38 | 18 |

|

|

| 60 | 2-H7009HQ1/2-H7007HQ1 |

|

170MD07Z8.5 | 8.5/5 | 350 | 19/11.5 | 7000 | 234 | 170 | 320 | 120 | 117 | 50 | 24 | 33 | 52 | M33*1.5 | 27 | 3-VEX55/2-VEX45 |

|

170MD09Z20 | 20/12.5 | 350 | 43 | 9000 | 300 | 170 | 383 | 124 | 70 | 50 | 24 |

|

|

|

| 3-B7011/2-B7009 |

|

210MD09Z33 | 33/20.6 | 350 | 70/43.8 | 9000 | 300 | 210 | 403 | 140 | 44 | 55 | 54 |

|

|

|

| 2-B7212/2-B7009 | 2GDZ09 |

170MD07Z8.5W | 8.5/5 | 350 | 19/11.5 | 7000 | 234 | 170 | 320 | 120 | 117 | 50 | 74 |

|

|

|

| 3-VEX55/2-VEX45 | 2GDZ07 |

200MD06Z8 | -/8 | 380 | -/15 | 6000 | 100 | 200 | 370 | 150 | 97 | 57 | 54 |

|

|

|

| 3-B7012/2-B7010 |

|

200MD06Z20 | -/20 | 350 | 42.5 | 6000 | 200 | 200 | 491 | 150 | 58 | 50 | 80 |

|

|

|

| 2-7212AC/2-7009AC |

|

230MDF06Z40 | -/40 | 380 | 75 | 6000 | 200 | 230 | 763 | - | - | - | - |

|

|

|

| 4-B7017/2-7013 |

|

180MD03Z10B | -/10 | 380 | 21 | 3000 | 100 | 180 | 530 | 165 | 20 | - | - |

|

|

|

| 4-7016/2-7011 |

|

200MD03Z12 | 12/8 | 350 | 18.5 | 3000/2100 | 100/70 | 200 | 470 | 165 | 100 | 75 | 15 |

|

|

|

| 4-7016/2-7010 |

|

240MD03Z16 | -/16 | 380 | -/32 | 3000 | 100 | 240 | 415 | 178 | 104 | 80 | 20 |

|

|

|

| 4-7017/2-7013 |

|

260MD03Z24B | 15 | 380/350 | 33/36 | 3000/1500 | 100/50 | 260 | 423 | 165 | 57 | 75 | 15 |

|

|

|

| 3-7016/2-7013 |

|

240MD015Z10 | 10/6.25 | - | 30/18.7 | 1500 | 50 | 240 | 410 | 190 | 92 | 85 | 24 |

|

|

|

| 3-7017/2-7012 | GDZ015 |

80MD150Q0.8 | 0.8/5.5 | 350 | 3/1.43 | 150000 | 2500 | 80 | 110 | 8 | 12 | - | - | 3.175 | 14 | - | - | 1-VEB08NS/1-VEB08NS |

|

80MD120Q0.9 | 0.9/0.55 | 220 | 4.6/2.8 | 120000 | 2000 | 80 | 150 | 48 | 8 | 10 | 5 | 5 | 9 | M5 | 8 | 1-VEB10/1-VEB10 |

|

120MD100Q2.5 | -/2.5 | 200 | -/9 | 100000 | 1667 | 120 | 177 | 75 | 3.5 | 19 | 8 | 11 | 8 | M10*1.25 | 12 | 1-71904/1-71903 |

|

120MD75Q8 | 85 | 350 | 18.4/11.5 | 75000 | 1250 | 120 | 210 | 80 | 25 | 18.5 | 13 | 10 | 19 | M1081.5 | 19 | 2-VEX20NS/2-VEX17NS |

|

100MD60Q6 | 6/3.6 | 350 | 16/10 | 60000 | 1000 | 100 | 255 | - | - | 28 | 9 | 8 | 16 | M8*1 | 15 | 2-VEX30NS/2-VEX20NS | 2GDZ60Q |

100MD60Q9 | -/9 | 350 | 13.3 | 60000 | 1000 | 100 | 255 | - | - | 28 | 9 | 16 | 23 | M16*1.5 | 30 | 2-VEX30NS/2-VEX20NS |

|

140MD60Q9 | 9/5.5 | 350 | 13.3/8.3 | 60000 | 1000 | 149.8 | 260 | 129.7 | 50 | 53 | 13.5 | 16 | 25 | M16*1.5 | 19 | 2-VEX30NS/2-VEX25NS |

|

170MD60Q(HW) | 7.5/4.5 | 380 | 14.4/9 | 48000/60000 | 800/1000 | 170 | 220 | - | - | 28 | 6.5 | 16 | 24 | M16*1.5 | 20 | 2-VEX30NS/2-VEX25NS |

|

120MD51Q8 | 8/4.8 | 350 | 20/12 | 51000 | 850 | 120 | 232 | 80 | 30 | 23 | 10 | 14 | 23 | M14*1.5 | 19 | 2-B7005/2-B7004 |

|

170MD36Q13.6 | 13.6/8.5 | 350 | 28.6/18 | 36000 | 600 | 170 | 390 | 115 | 47 | 43 | 32 | 25 | 38 | M25*2 | 29 | 2-VEX45NS/2-VEX35NS |

|

120MD30Q12 | 19/12 | 350 | 49/31 | 30000 | 1000 | 120 | 370 | - | - | 43 | 15 | 28 | 44 | M28*2 | 29 | 2-VEX45NS/2-VEX30NS |

|

170MD30Q32H | 32/21 | 350 | 46 | 30000 | 1000 | 170 | 340 | 126 | 45 | 53 | 27 | 32 | 46 | M32*2 | 25 | 2-H7011CHQ1/2-H7009CHQ1 |

|

150MD30Q23 | 23/14.4 | 380 | 49/30 | 30000 | 1000 | 149.8 | 260 | 129.7 | 50 | 53 | 13.5 | 32 | 50 | M32*2 | 26 | 2-VEX55NS/2-VEX40NS |

|

150MD21Q18 | 18/11 | 380 | 35.5/21.4 | 21000 | 350 | 150 | 320 | 110 | 38 | 43 | 18 | 25 | 40 | M25*2 | 30 | 2-B7009/2-B7008 |

|

170MD24Q30H | 30/19 | 350 | 41 | 24000 | 800 | 170 | 340 | 136 | 45 | 63 | 27 | 36 | 50 | M36*2 | 30 | 2-H7014CHQ1/2-H7009CHQ1 |

|

170MD12Q40H | 40/30 | 350 | 58 | 12000 | 600 | 170 | 415 | 137 | 49 | 68 | 27 | 40 | 50 | M40*2 | 30 | 2-H7014CHQ1/2-H7009CHQ1 |

|

210MD09Q46H | 46/33 | 350 | 70 | 9000 | 300 | 210 | 560 | 190 | 24 | 97 | 30 | 48 | 55 | M48*2 | 40 | 2-H7020CHQ1/2-7211CP4 | |

To learn more about ZYS other series of electrical spindles, mechnical center spindles, please visit https://www.zys-bearing.com/spindles/.

_副本1616727918.jpg)