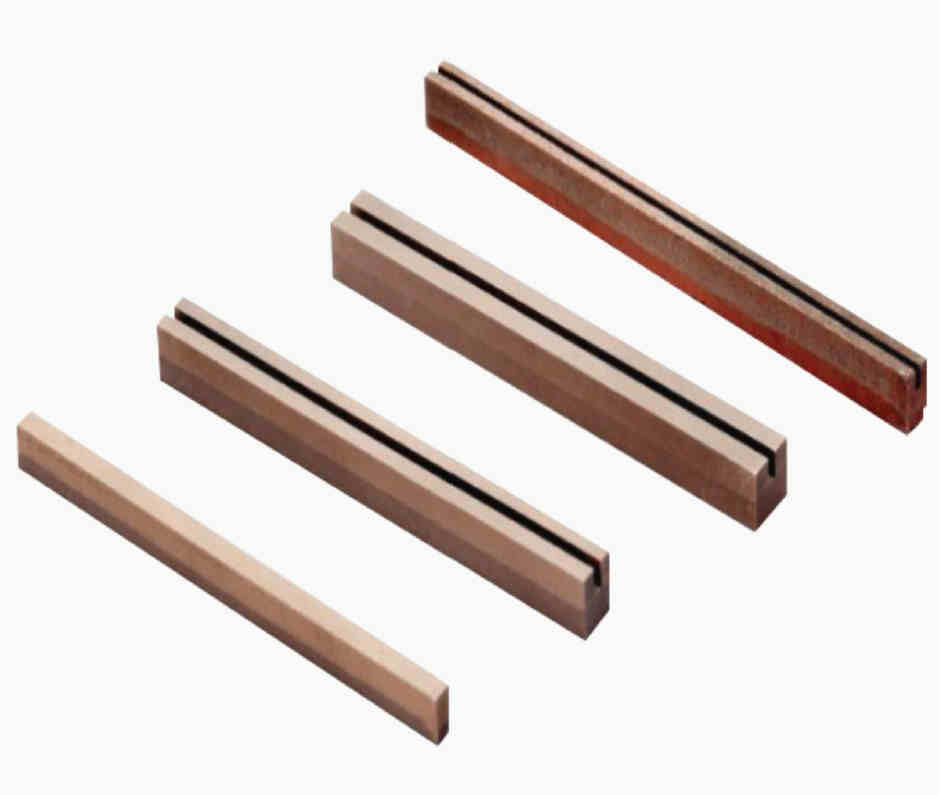

Application areas of Honing Whetstone:

Engine cylinder liners and cylinder blocks of automobiles, motorcycles, and construction machinery,connecting rod inner hole, brake hub, oil pump, oil nozzle, gear, air conditioning compressor cylinder, hydraulic cylinder, bearing, etc.

Processing materials of Honing Whetstone:

Cast iron, silicon aluminum alloy, babbitt alloy, bronze, brass, glass, ceramics, tool steel, die steel, quenched steel, high temperature alloy steel, high chromium cast iron, heat resistant alloy steel, etc.

Main feature of Honing Whetstone:

High efficiency, good surface quality, high durability and good shape retention.

Models of Honing Whetstone:

HMA/1, HMA/2, HMH, 2HMA, HMA/S0, HA, HH, etc. Various products can also be customized according to user needs.

The honing process is a special form of grinding, and it is also an efficient processing method in finishing.It can remove large allowance to be processed, improve the dimensional accuracy, geometric accuracy and surface quality of parts, and has been widely used in the manufacture of auto parts.

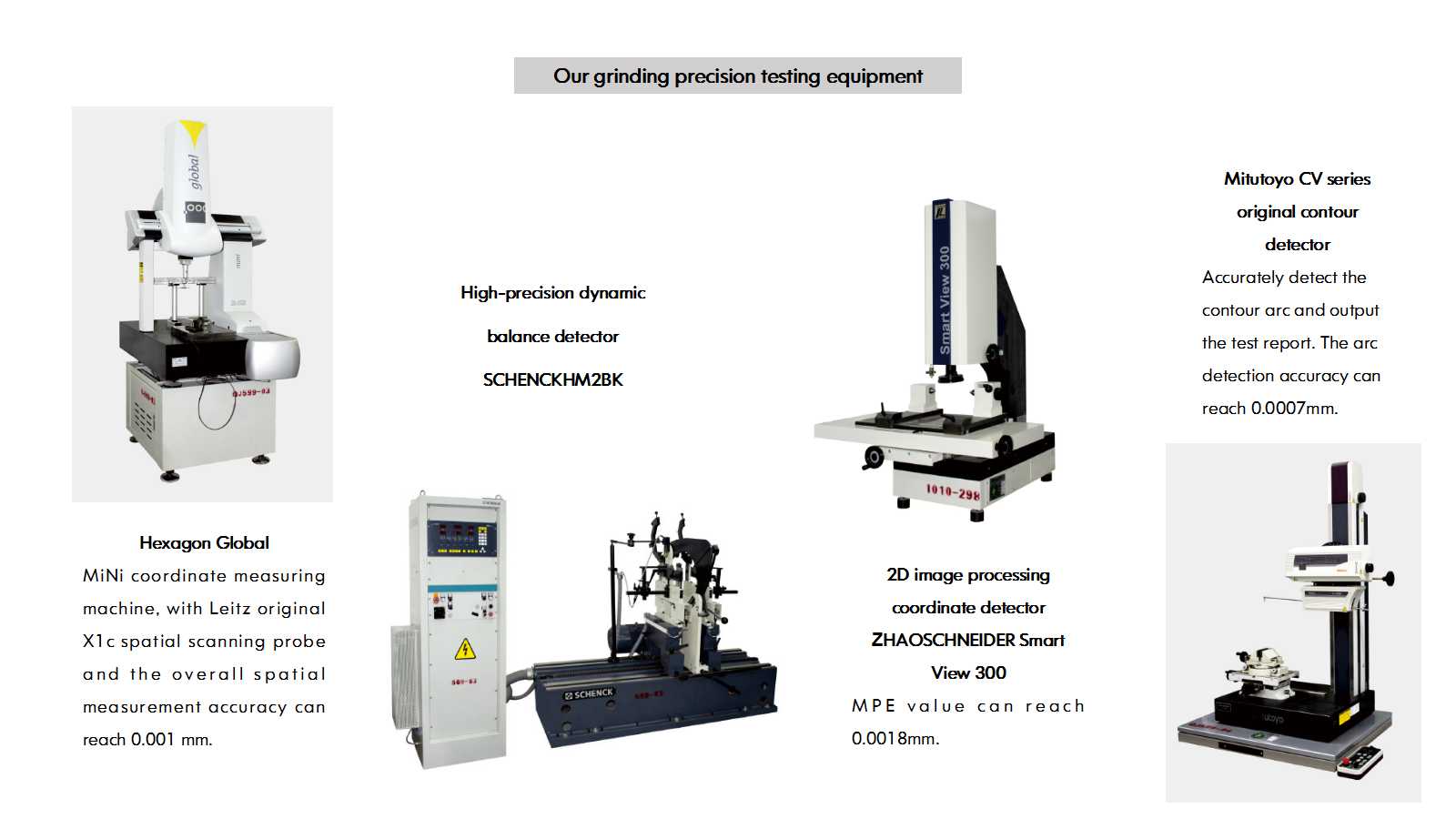

Company advantages

We are a comprehensive technology enterprise specializing in R&D, production, sales of superhard material products and providing overall solutions.

We own dozens of production lines on vitrified bond, resin bond, metal bond and electroplated bond superabrasive products, equipments and inspection instruments which have yearly capacity with six hundred thousand pieces of superabrasive tools and more than three thousands sets of machines. Our main products are fixed abrasives (including ceramic abrasives, resin abrasives, rubber abrasives, etc.), coated abrasives (sand belts, abrasive cloth sandpaper, special-shaped products, etc.), super-hard materials, which are widely used in the steel, automobile, gear, bearing, metal, wood processing and other industries, with tens of thousands of product specifications. It has an annual production capacity of 8,000 tons of bonded abrasives, 5 million square meters of coated abrasives and 10 million carats of diamond/CBN products.

The product quality is excellent, and the grinding wheel technology for parts processing in refrigeration, automotive, electronics and other industries is at the international leading level. The market share of grinding wheels for parts processing reaches 50%~80%, and our products are exported to Brazil, Japan, India, Southeast Asia and other countries and regions.

Our environment management system is in conformity with GB/T 24001-2016/ISO 12001:2015; the quality management system is in conformity with GB/T 19001-2016/ISO 9001:2015.

Production capacity