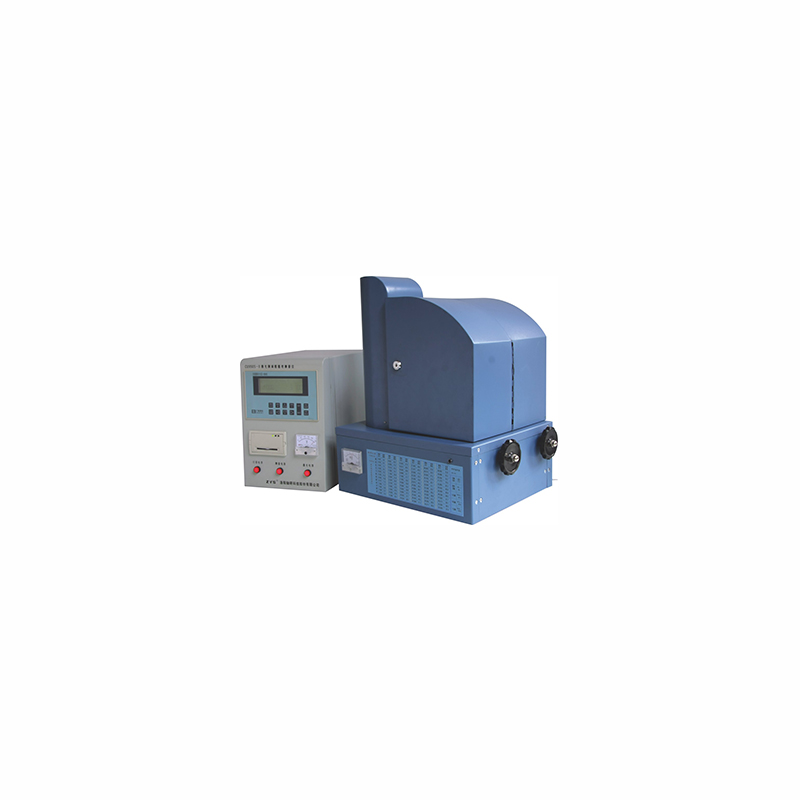

Application: Measuring and judging high precision steel ball roughness in ball factory.

Features of steel ball roughness measuring instrument:

1. Protection of workpiece: non-contact laser measurement to protect the part surface under test

2. High efficiency: display Ra value and grade directly after placing balls.

3. High precision: Especially suitable for steel balls with high finish. It reduces the mechanical filtering phenomenon which stylus measurement has and improves the accuracy.

Steel ball roughness measuring instrument | Type | Measuring range | Ra measuring range | Indication error | Efficiency | Ry measuring range | Indication repeatability | ||

CU9505B | Steel ball diameter φ3-70mm | 0.005-0.32μm | <15% | About 150 pcs/hour | 0.01-0.32μm | >95% | |||

Outer dimension | 450*350*570 (mechanical) 260*320*370 (electrical) |

|

|

|

|

| |||

Ring and raceway roughness measuring instrument | Type | Size range of measured ring | Indication error | Efficiency | Ra measuring range | Indication repeatability | |||

Outer diameter (outer ring/ inner ring) | Radius of raceway curvature | Width |

|

|

|

| |||

CU0008 | φ30-80mm/ φ17-52mm | R2.5-6.2mm | 9-18mm | <15% | About 120 pcs/hour | 0.020-0.32μm | >95% | ||

CU0013 | Φ40-130mm/ φ23-75mm | R3-9mm | 12-25mm | <15% | About 120 pcs/hour | 0.020-0.32μm | >95% | ||