In order to promote the company's high-quality development, improve the professional skills of the inspection team, and strengthen the spirit of teamwork, the company held the 2024 "Inspection Elite,Quality Pioneer" Inspector Skills Competition from September 18th to 19th, with a total of 24 employees participating. This competition adopts a combination of theoretical and practical examinations, aiming to comprehensively evaluate the contestants' professional skills, theoretical knowledge and practical operational capabilities.

At 9:00 am on the 18th, 24 employees arrived at the examination room on time to take the theoretical examination. The theoretical examination paper was carefully designed around the basic knowledge of bearings and inspection operation specifications. The one-hour examination was intended to encourage employees to develop good habits of actively learning new knowledge, new skills and mastering new processes. To ensure the fairness, impartiality and professionalism of the exam, a sealed system was strictly implemented throughout the entire process from test paper design to distribution, and every link was strictly controlled.

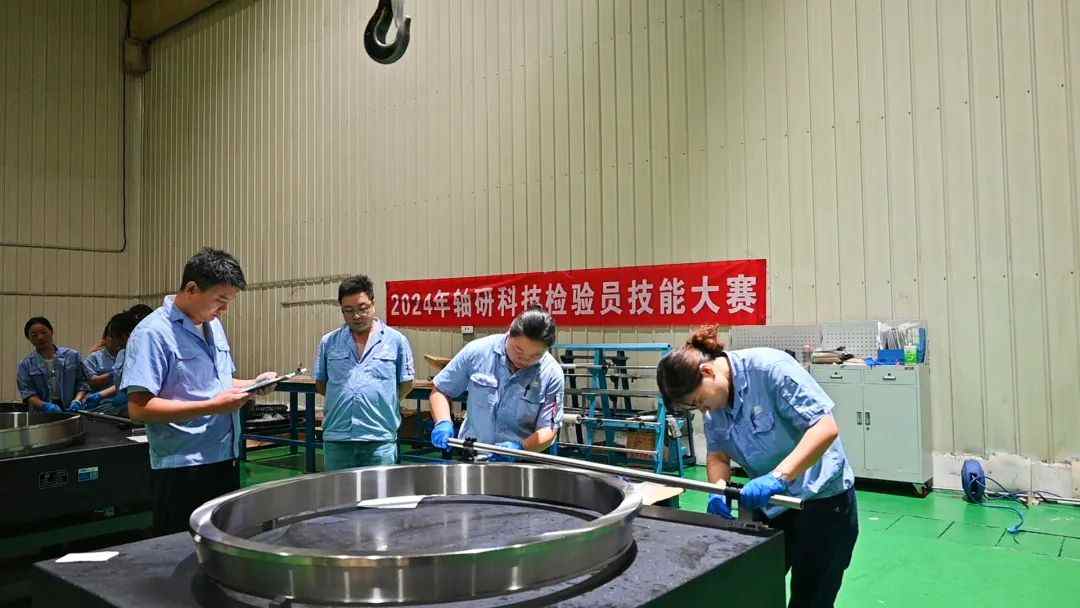

During the practical test on the 19th, the participating employees were full of enthusiasm and the workshop was filled with a tense and exciting atmosphere. The actual operation assessment covers multiple key processes such as product inspection, equipment operation, and problem diagnosis. It requires employees to be proficient in debugging skills, independently complete the interpretation of the ring processing process card, and accurately use inspection equipment such as gauge blocks and instruments to calibrate pipe dimensions. After debugging is completed, employees need to test the inner diameter size, accuracy and inner diameter appearance quality of the ring in turn. The invigilator carefully observes each employee's operating skills, safety awareness, quality control and analysis capabilities, and scores them one by one according to the scoring criteria.

After two days of fierce competition and fair judging, Li Jiaojiao won the first prize, Zhang Jingfang won the second prize, Sun Aqin won the third prize, and Liu Haile, Pan Junmei and Chen Fuguang won the Excellence Prize. Deputy General Manager Li Qiang and Labor Union Chairman Wang Feng presented awards to the winning employees. Li Qiang said that this inspector skills competition is one of the important measures for the company to strengthen the construction of the quality management system and improve the level of product quality control. Through the competition, we can not only effectively improve the professional quality and practical operation ability of inspectors, but also stimulate their work enthusiasm and team spirit, laying a solid foundation for the company's high-quality development.

In the future, ZYS will continue to increase its efforts in employee training and management, constantly improve the construction of the quality management system, and ensure that product quality always remains at the forefront of the industry. At the same time, the company will actively introduce advanced quality inspection technologies and equipment to improve the accuracy and efficiency of product quality inspection and provide customers with better quality and more efficient products and services.