Since the beginning of 2023, ZYS has fully implemented its work deployment, anchored the theme of "high-quality development", promoted the spirit of "putting practical work first and putting work first", and made stable growth a top priority in its work. As of the end of March, ZYS achieved a year-on-year growth of 17.1% in its first quarter revenue and profit increased by 35.9% year-on-year, achieving a successful start.

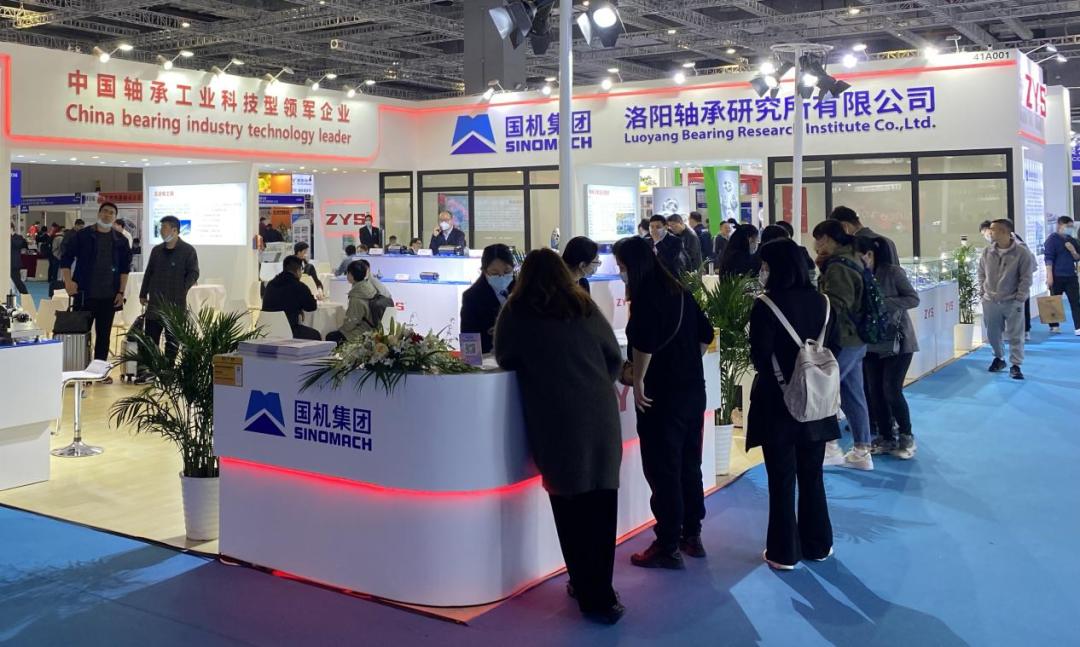

ZYS actively integrates into the new development pattern, plans from a high starting point, meets high standards, seizes development opportunities, and identifies the right direction for development. ZYS has continuously held work mobilization meetings and business analysis meetings to comprehensively deepen the special action of science and technology reform demonstration, and accelerate the promotion of the talent strong enterprise strategy. Taking the opportunity of participating in the Shanghai Bearing Exhibition, we continuously visit key customers, continuously explore market demand, strengthen technical exchanges and services, and improve our supply guarantee and after-sales capabilities.

ZYS Special Bearings Division vigorously promoted regional marketing, developed 8 new customers, completed 61 new model products, focused on developing bearings for power systems, and formed batch sales orders. ZYS actively carried out supply guarantee and production promotion activities, implemented fixed quantity and production management for key processes, and fully ensured the timely delivery of key products.

ZYS Equipment Testing Division deepened the integration of internal and external resources, optimized business layout, and formed a collaborative and efficient competitive advantage. Targeting high-end market demands such as universities and research institutes, we selected key technical personnel from various businesses to accurately identify customer needs. ZYS further strengthened team construction and made every effort to ensure the smooth completion of the project.

ZYS Precision Parts Division achieved product process control through an integral system, effectively improving product quality. The product research and development department has designed and developed more than 10 new models of bearing products, while the spindle manufacturing department has developed 6 new products and 27 product optimization designs. We carried out precision machining of product parts, converted results based on research, and applied for one invention patent.

ZYS Manufacturing Services Division focused on market demand, strengthened collaborative research and achievement transformation of high-temperature lubrication technology, promoted the expansion of PEEK wear-resistant sliders into the field of imine film stretching with higher operating speeds, and integrated high-temperature self-lubricating imine and high-temperature lubricating grease technology. We rely on the mass production system of ceramic balls, optimize the production process of special steel balls, and lay the foundation for market expansion.

ZYS employees closely focus on the annual goals and tasks, and comprehensively open up a new situation for work in 2023 in a lean and efficient manner.

ZYS will lead the year with a "good start" and strive to achieve various production and operation goals throughout the year, achieving greater success in accelerating the construction of a first-class modern enterprise in China, and making new and greater progress in accelerating the promotion of high-quality development.