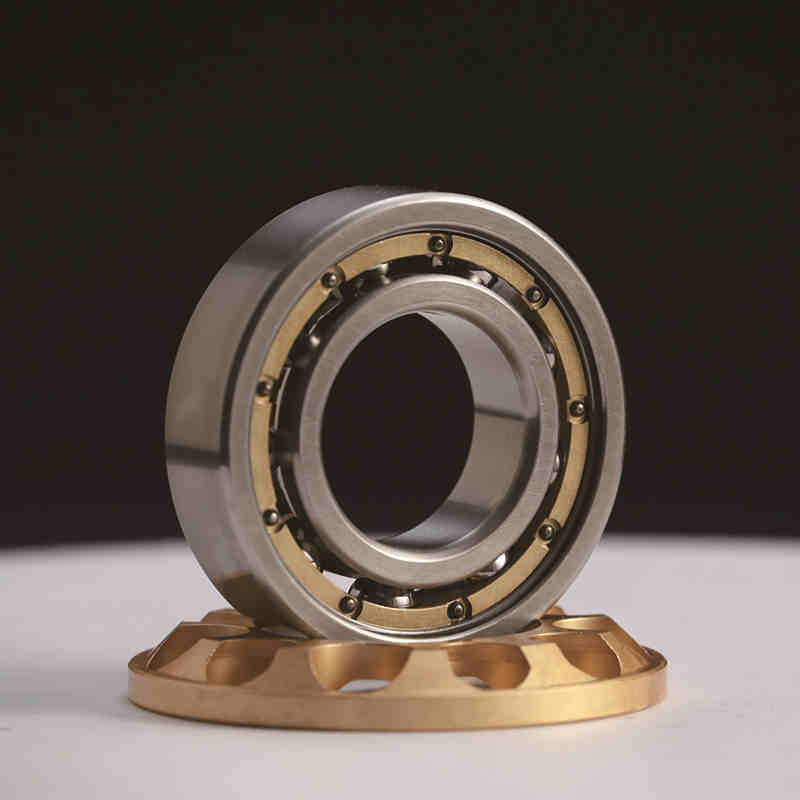

Product features of ZYS deep groove ball bearing:

Bearing inner and outer ring: The inner ring, outer ring and rolling elements of the bearing form an organic rotating unit. The inner and outer rings of ZYS deep groove ball bearings are made of GCr15 high-quality steel. The steel has high density and good ductility, which effectively prolongs the service life of the bearing.

Bearing rolling elements: The rolling elements transfer the load between the inner ring and the outer ring. ZYS deep groove ball bearings use G10 national standard steel balls to ensure stable operation and low noise.

Bearing cage: The bearing cage can reduce the frictional heat, optimize the load, keep the rolling elements in the correct position and interval, and prevent the rolling elements from falling off during installation. ZYS deep groove ball bearings use steel stamping cage or brass solid cage.

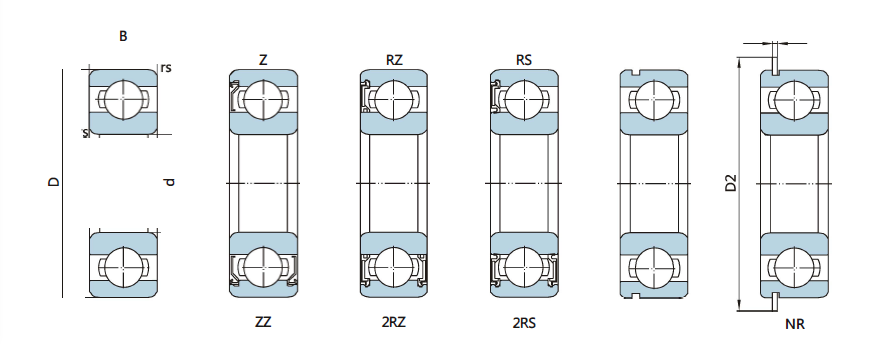

Bearing seal:

ZYS can provide deep groove ball bearings with different sealing structures, including open type (No shields), ZZ type (Metal shields), 2RS type (Contact rubber seals), 2RZ type (Non-contact rubber shields).

RS type (Contact rubber seals): The rubber seal material can effectively prevent foreign matter (liquid state) and impurities from intruding into the bearing and causing internal damage to the bearing. It has a good mute effect and is suitable for harsh environments.

ZZ type (Metal shields): The sealing material is stainless steel, which can effectively prevent external impurities from invading the bearing and causing internal damage to the bearing. It has low friction resistance, fast heat dissipation, high temperature resistance, high speed, and it is suitable for relatively clean working conditions.

Open type (No shields): The steel ball can be seen directly without a seal, which is suitable for a sealed environment such as a gear box and an environment with a lot of oil. The friction resistance is small, the idling effect is good, and the speed is super high.

Bearing clearance:

Advantages of ZYS deep groove ball bearings:

1.Low noise: ZYS adopts advanced silent manufacturing technology to produce energy-saving and environmentally-friendly high performance bearings, featuring low noise, low torque, low temperature rise, high limit speed, and low friction.

2.High precision: ZYS adopts new materials and special structure design, and uses high-efficiency polishing technology, so that ZYS bearing product has the characteristics of good sealing, low running resistance, and high rotation accuracy.

3. Long life: ZYS adopts hot rolling technology and special heat treatment process to improve the bearing's high temperature resistance, wear resistance, impact resistance, high load capacity and other properties, and enhance the reliability and service life of the bearing.

Why choose ZYS bearing:

ZYS has an independent R&D center and a core technology system with independent intellectual property rights. ZYS technical team and R&D equipment scale are at the forefront of the bearing industry. ZYS has many scientific research, testing and service institutions such as the National Bearing Quality Supervision and Inspection Center and the National Bearing Accreditation Laboratory. ZYS has achieved 908 major scientific research projects and has 792 authorized patents.

Simulation analysis and design technology: ZYS has a post-doctoral research station, an experienced team of domestic and foreign experts, complete bearing professional analysis and finite element analysis software, which can systematically analyze and design the mechanics, kinematics and dynamics properties of bearings and bearing components.

Material technology: ZYS specializes in the research and development of bearing special steel, forming and heat treatment technology, bearing lubrication and sealing materials to ensure that the bearings can meet the requirements of various complex working conditions such as long life, impact resistance, heavy load, high and low temperature.

Simulation bench test technology: ZYS possesses test technical specifications, test equipment, and test equipment development capabilities and test data processing and analysis capabilities for various types of bearings under various working conditions, providing strong support for customer product development.

Professional application technical services: ZYS has more than 380 engineering and technical personnel in bearing-related disciplines, and maintains a leading position in bearing design, basic theoretical research, lubrication technology, metal and non-metal materials, testing, and industrial standards. ZYS professional service team provides customers with systematic bearing application technology solutions including bearing selection, design, materials, testing, and process equipment.

Technical parameters of ZYS deep groove ball bearings:

Bearing Model | Dimension | Basic Load rating (kN) | Weight (kg) | |||||||||||

Standard type | shield | seal | With snap ring groove | With snap ring | d | D | B | rsmin | D2 (max) | max | Cr | Cor |

| |

624 | ZZ | 2RZ | 2RS | N | NR | 4 | 13 | 5 | 0.2 | - | - | 1.15 | 0.4 | 0.0031 |

625 | ZZ | 2RZ | 2RS | N | NR | 5 | 16 | 5 | 0.3 | - | - | 1.88 | 0.68 | 0.0048 |

626 | ZZ | 2RZ | 2RS | N | NR | 6 | 19 | 6 | 0.3 | - | - | 2.80 | 1.05 | 0.0081 |

627 | ZZ | 2RZ | 2RS | N | NR | 7 | 22 | 7 | 0.3 | - | - | 3.28 | 1.35 | 0.013 |

628 | ZZ | 2RZ | 2RS | N | NR | 8 | 24 | 8 | 0.3 | - | - | 3.35 | 1.40 | 0.017 |

629 | ZZ | 2RZ | 2RS | N | NR | 9 | 26 | 8 | 0.3 | - | - | 4.45 | 1.95 | 0.020 |

6200 | ZZ | 2RZ | 2RS | N | NR | 10 | 30 | 9 | 0.6 | - | - | 5.1 | 2.39 | 0.032 |

6201 | ZZ | 2RZ | 2RS | N | NR | 12 | 32 | 10 | 0.6 | 36.7 | 1.12 | 6.00 | 2.70 | 0.036 |

6202 | ZZ | 2RZ | 2RS | N | NR | 15 | 35 | 11 | 0.6 | 39.7 | 1.12 | 7.80 | 3.75 | 0.045 |

6203 | ZZ | 2RZ | 2RS | N | NR | 17 | 40 | 12 | 0.6 | 44.6 | 1.12 | 9.56 | 4.75 | 0.065 |

6204 | ZZ | 2RZ | 2RS | N | NR | 20 | 47 | 14 | 1 | 52.7 | 1.12 | 12.7 | 6.55 | 0.103 |

6205 | ZZ | 2RZ | 2RS | N | NR | 25 | 52 | 15 | 1 | 57.9 | 1.12 | 14.0 | 7.80 | 0.127 |

6206 | ZZ | 2RZ | 2RS | N | NR | 30 | 62 | 16 | 1 | 67.7 | 1.7 | 19.5 | 11.2 | 0.203 |

6207 | ZZ | 2RZ | 2RS | N | NR | 35 | 72 | 17 | 1.1 | 78.6 | 1.7 | 25.5 | 15.3 | 0.287 |

6208 | ZZ | 2RZ | 2RS | N | NR | 40 | 80 | 18 | 1.1 | 86.6 | 1.7 | 30.7 | 19.0 | 0.367 |

6209 | ZZ | 2RZ | 2RS | N | NR | 45 | 85 | 19 | 1.1 | 91.6 | 1.7 | 33.2 | 21.6 | 0.416 |

6210 | ZZ | 2RZ | 2RS | N | NR | 50 | 90 | 20 | 1.1 | 96.5 | 2.46 | 35.1 | 23.2 | 0.462 |

6211 | ZZ | 2RZ | 2RS | N | NR | 55 | 100 | 21 | 1.5 | 106.5 | 2.46 | 43.4 | 29.2 | 0.607 |

6212 | ZZ | 2RZ | 2RS | N | NR | 60 | 110 | 22 | 1.5 | 116.6 | 2.46 | 47.5 | 32.5 | 0.783 |

6213 | ZZ | 2RZ | 2RS | N | NR | 65 | 120 | 23 | 1.5 | 129.7 | 2.82 | 55.9 | 40.5 | 0.990 |

6214 | ZZ | 2RZ | 2RS | N | NR | 70 | 125 | 24 | 1.5 | 134.7 | 2.82 | 60.5 | 45.0 | 1.10 |

6215 | ZZ | 2RZ | 2RS | N | NR | 75 | 130 | 25 | 1.5 | 139.7 | 2.82 | 66.3 | 49.0 | 1.20 |

6216 | ZZ | 2RZ | 2RS | N | NR | 80 | 140 | 26 | 2 | 149.7 | 2.82 | 70.2 | 55.0 | 1.40 |

6217 | ZZ | 2RZ | 2RS | N | NR | 85 | 150 | 28 | 2 | 159.7 | 2.82 | 83.2 | 64.0 | 1.80 |

6218 | ZZ | 2RZ | 2RS | N | NR | 90 | 160 | 30 | 2 | 169.7 | 2.82 | 95.6 | 73.5 | 2.15 |

6219 | ZZ | 2RZ | 2RS | N | NR | 95 | 170 | 32 | 2.1 | 182.9 | 3.1 | 108 | 81.5 | 2.60 |

6220 | ZZ | 2RZ | 2RS | N | NR | 100 | 180 | 34 | 2.1 | 192.9 | 3.1 | 122 | 92.7 | 3.20 |

6221 | ZZ | 2RZ | 2RS | N | NR | 105 | 190 | 36 | 2.1 | 202.9 | 3.1 | 133 | 104 | 3.71 |

6222 | ZZ | 2RZ | 2RS | N | NR | 110 | 200 | 38 | 2.1 | 212.9 | 3.1 | 144 | 117 | 4.44 |

6224 | ZZ | 2RZ | 2RS | N | NR | 120 | 215 | 40 | 2.1 | 227.8 | 3.1 | 155 | 130 | 5.32 |

6226 | ZZ | 2RZ | 2RS | N | NR | 130 | 230 | 40 | 3 | 242 | 3.5 | 165 | 147 | 6.13 |

6228 | ZZ | 2RZ | 2RS | N | NR | 140 | 250 | 42 | 3 | 262 | 3.5 | 165 | 125 | 7.45 |

6230 | ZZ | 2RZ | 2RS | -- | - | 150 | 270 | 45 | 3 | -- | - | 174 | 137 | 9.40 |

6232 | ZZ | 2RZ | 2RS | -- | -- | 160 | 290 | 68 | 3 | -- | - | 185 | 186 | 12.8 |

6234 | ZZ | 2RZ | 2RS | -- | - | 170 | 310 | 52 | 4 | -- | - | 212 | 224 | 15.8 |

6236 | ZZ | 2RZ | 2RS | -- | - | 180 | 320 | 52 | 4 | -- | - | 227 | 241 | 15.9 |

6238 | ZZ | 2RZ | 2RS | -- | - | 190 | 340 | 55 | 4 | -- | - | 255 | 282 | 22.3 |

6240 | ZZ | 2RZ | 2RS | -- | - | 200 | 360 | 58 | 4 | -- | - | 269 | 310 | 26.7 |

6244 | ZZ | 2RZ | 2RS | -- | - | 220 | 400 | 65 | 4 | -- | - | 310 | 375 | 37.4 |

6248 | ZZ | 2RZ | 2RS | -- | - | 240 | 440 | 72 | 4 | -- | - | 340 | 430 | 50.5 |

6252 | ZZ | 2RZ | 2RS | -- | - | 260 | 480 | 80 | 5 | -- | - | 400 | 540 | 67 |

6256 | ZZ | 2RZ | 2RS | -- | - | 280 | 500 | 80 | 5 | -- | - | 400 | 550 | 70.4 |

6260 | ZZ | 2RZ | 2RS | -- | -- | 300 | 540 | 85 | 5 | -- | - | 465 | 670 | 87.8 |

MACHINE TOOL

Machine tool is the carrier of advanced manufacturing technology and the basic production means of equipment industry. It is the basic equipment for equipment manufacturing industry, mainly for automobile, military, agricultural machinery, engineering machinery, electric power equipment, railway locomotive, ship and other industries. Machine tool performance plays an increasingly important role in production efficiency and product quality and also has high demand for more reliable and energy efficient components.

LEARN MORE >

VEHICLE

Driven by increasing environmental awareness and stricter emission regulations, the automotive industry is undergoing an unprecedented period of change. Computer technology has been used in the control and monitoring devices of many vehicle systems. New materials for cars, such as light alloys, have been gradually used in mainstream cars, and new technologies allow for further emissions cuts.

LEARN MORE >

RAILWAY

Railway transportation is one of the main ways of transportation. As the main means of railway transportation, train technology is constantly innovating. Freight vehicles with increasing load, locomotive vehicles with increasing traction, or passenger vehicles with increasing running speed are affecting people's way of life.

LEARN MORE >

MOTORCYCLE

Each motorcycle is usually equipped with 20 to 30 bearings. These bearings are used for important rotating parts such as engines, transmissions, and wheels to support driving, and are responsible for reducing friction and driving the engine power to the wheels. Therefore, the performance required for motorcycle bearings is to achieve smooth rotation through low friction, low vibration and high durability. These performance affect the fuel consumption and safety that are closely related to our life. ZYS always pays attention to these details and strives to develop bearing and optimize the bearing design to improve the quality of life and protect the global environment.

LEARN MORE >

AGRICULTURE

Agricultural engineering involves a wide range of machinery, equipment and tools, most of which are specially designed and manufactured according to the characteristics of agriculture and the special requirements of various operations, such as soil tillage machinery, planting and fertilization machinery, plant protection machinery, crop harvesting machinery, animal husbandry machinery and agricultural products processing machinery, etc. Another part of agricultural machinery is common to other industries, and can be directly selected according to the characteristics and needs of agriculture, such as agricultural power machinery, water pumps in farmland irrigation and drainage machinery, etc.; or design these machinery into agricultural variants according to the characteristics and needs of agriculture, such as agricultural vehicles, trailers in agricultural transport machinery, stone machinery in farmland construction machinery.

LEARN MORE >

ELECTRIC MOTOR

Motors are used as power sources in all industries. In the development of the electrification of power sources, in order to meet the requirements of environmental protection, low energy loss and high reliability, ZYS continuously developed high-performance bearings with low friction. These bearings are widely used in the rotating part of the motor, which can play a significant role in bearing the load carried by the motor while supporting smooth and quiet rotation.

LEARN MORE >

METALLURGY AND CONSTRUCTION